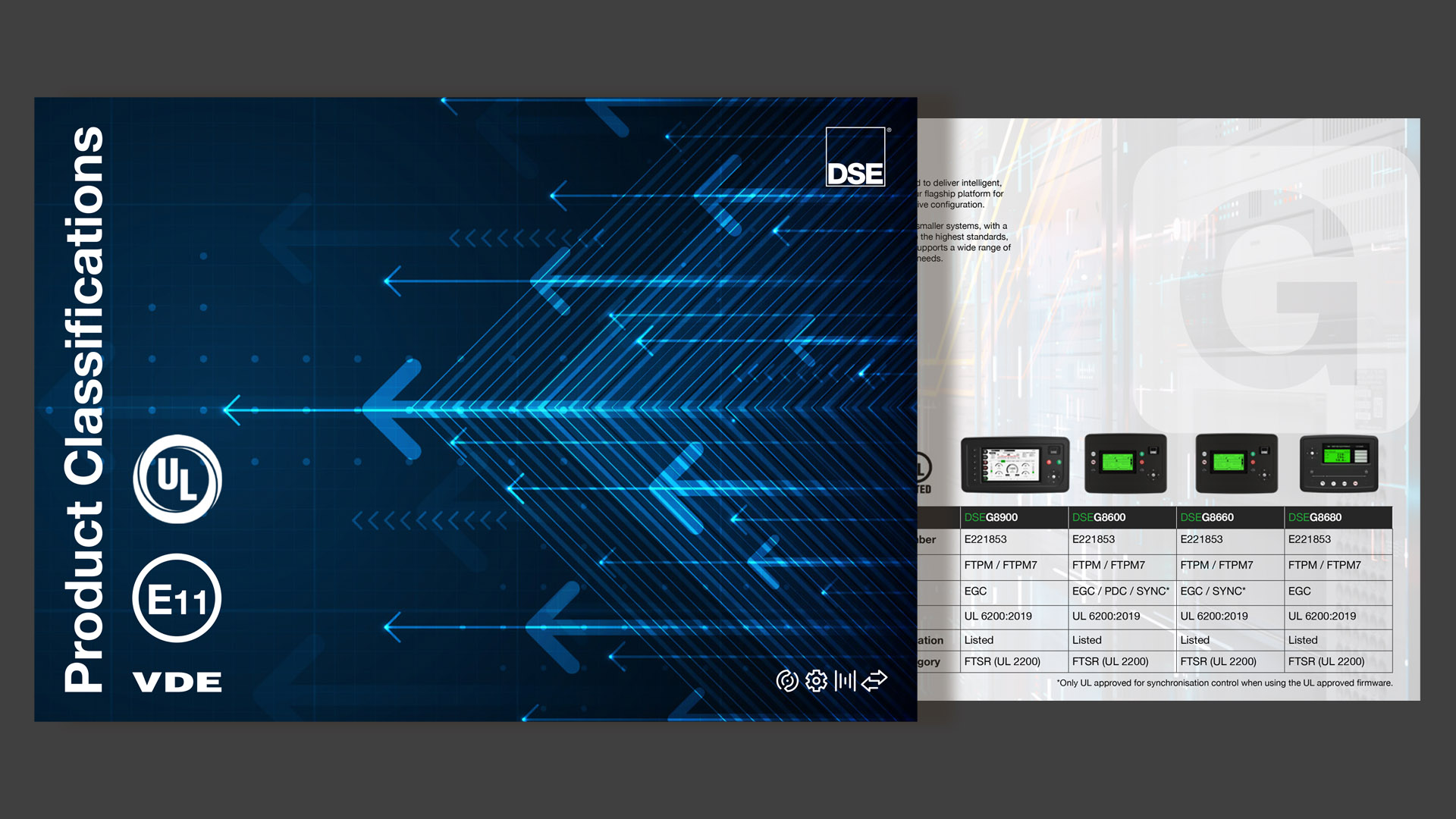

Advanced Paralleling Gen-Set Controllers

DSEG8600

Parallel Genset Controller with Integral Heater

The G8600 is a parallel genset controller with integral heater designed for complex paralleling applications. The G8600 can be configured to provide paralleling for up to 4,032 generators on a single site and provides a wide range of high-end features for multiple application environments. The module is configurable for use as a single-set controller, multi-set controller, mains (utility) controller or group controller.

248 mm x 182.6 mm x 45.2 mm / 9.77” x 7.19” x 1.78”

Panel Cut-Out (W x H)

220 mm x 160 mm / 8.66” x 6.3”

Maximum Panel Thickness

8 mm / 0.31”

Request a Quote

Product Highlights

Key Features

- Additional Features

- Built-in governor & AVR control

- DSE digital AVR support

- Base load (kW export) control

- Positive & negative kVAr export control

- Dead bus synchronising

- Mains (utility) decoupling protection

- Multiple language support

- 3-phase generator sensing & protection

- 3-phase mains (utility) sensing

- 3-phase bus sensing

- Mains (utility) failure detection

- Generator current, protection & power monitoring

- Configurable timers

- Integrated SNMP

- Data logging

- PC configuration

- DSENet® Expansion Support

- Flexible I/O (inputs/outputs)

- Automatic and front panel breaker control

- Power-save mode

Specification

DC Supply

Continuous Voltage Rating8 V to 35 V DC continuous

Cranking Dropouts Able to survive 0 V for 100 mS, providing supply was at least 10 V before dropout and supply recovers to 5 V. This is achieved without the need for internal batteries. LEDs and backlight will not be maintained during cranking.

Maximum Operating Current

700 mA at 12 V, 350 mA at 24 V

Maximum Standby Current

350 mA at 12 V, 190 mA at 24 V

Charge Fail Excitation Range

0 V to 35 V

Real Time Clock Battery

Not replaceable

Voltage Measurement

Measurement Inputs3 ph + N

Measurement Range

15 V to 415 V (L-N) / 25 V - 719 V (Ph-Ph)

Accuracy

1% full scale

Frequency Range

3.5 Hz to 75 Hz

Input Impedance

450 K L-L

Current Measurement

Measurement Inputs3-phase & neutral

Measurement Range

0-1 A, 0-5 A

Max Allowed Continuous Current

5 A

Accuracy

1% full scale

Input Impedance

0.02 R

Inputs

Analogue4 sender inputs configurable 1 x 0-3 K, 3 x 0-5 K

Digital (Flexible)

3 configurable, active low / active high, 0-3 K resistance, 0-10 V, 0-32 V, 0-20 mA

Digital

9 active low digital outputs

Type

Standard senders with floating common, digital flex use system ground with separate return terminal

Resolution

1 R, 0.1 V, 0.1 mA

Accuracy

1% full range

Outputs

AnalogueGovernor / AVR configurable ±10 V, ±20 mA

Digital

Fuel / crank protected FET output 15 A

Auxiliary

8 protected FET @ 2 A

Switching To

Plant supply

Volt-Free Contact

2 volt-free contacts (C & D) 8 A at 250 V AC

AVR Governor Control

Minimum Load ImpedanceVoltage mode minimum = 500 R, Current mode max = 500 R

Gain Voltage

0-10 V, 0-20 mA configurable

Offset Voltage

0-10 V, 0-20 mA configurable

Magnetic Pick-Up

Voltage Input Range0.5 V to 70 V RMS

Frequency Input Range

1 Hz to 10 KHz

Frequency Measurement Tolerance

Better than 0.1%

Communications

RS485Fully isolated x 2

Ethernet

10/100 Ethernet Port

USB A

1 x storage device

USB B

1 x non isolated host / programming

CAN

Fully isolated x 3

Temperature

Operating Temperature-30° C to +70 ° C / -22° F to +158 ° F

Storage Temperature

-40° C to +85 ° C / -40° F to +185 ° F

Dimensions

Overall (W x H x D)248 mm x 182.6 mm x 45.2 mm / 9.77” x 7.19” x 1.78”

Panel Cut-Out (W x H)

220 mm x 160 mm / 8.66” x 6.3”

Maximum Panel Thickness

8 mm / 0.31”

Environmental Testing Standards

BS EN 61000-6-2 - EMC Generic Immunity Standard for the Industrial Environment

BS EN 61000-6-4 - EMC Generic Emission Standard for the Industrial Environment

Electrical Safety

BS EN 61010 - Safety of Information Technology Equipment, including Electrical Business Equipment

Temperature

BS EN 60068-2-1 - Ab/Ae Cold Test -30°C

BS EN 60068-2-2 - Bb/Be Dry Heat +70°C

Vibration

BS EN 60068-2-6 - Ten sweeps in each of three major axes

5Hz to 8 Hz at +/-7.5mm

8Hz to 500 Hz at 2gn

BS EN 60068-2-30 - Db Damp Heat Cyclic 20/55°C at 95% RH 48 Hours

BS EN 60068-2-78 - Cab Damp Heat Static 40°C at 93% RH 48 Hours

Shock

BS EN 60068-2-27 - Three shocks in each of three major axes

15 gn in 11 ms

Degrees of Protection Provided by Enclosures

BS EN 60529 - IP65 - Front of module when installed into the control panel (Integrated Gasket)

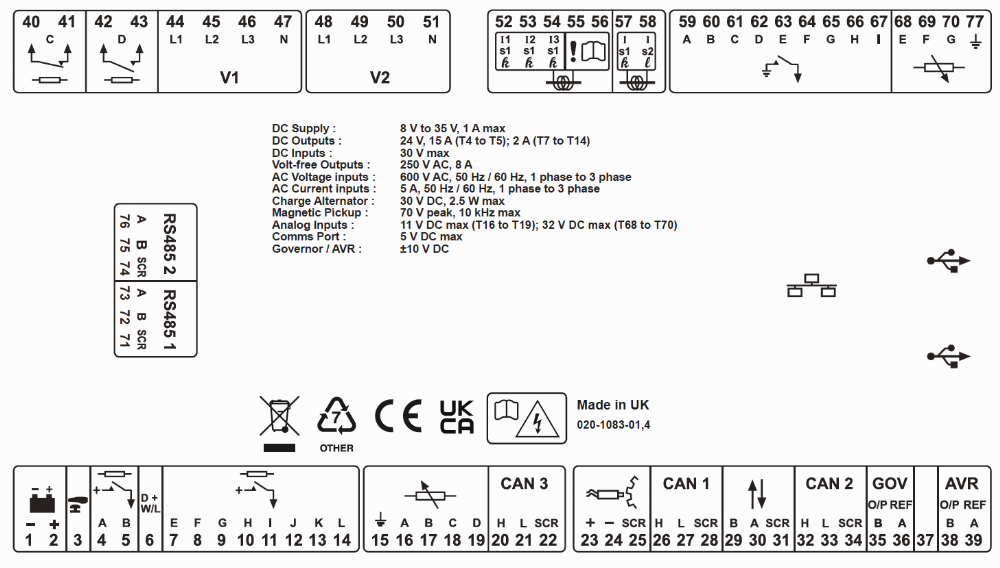

Connection Diagram