Load Sharing & Synchronising Control Modules

DSE8610 MKII

Synchronising & Load Sharing Auto Start Control Module

Overall (W x H x D)

245 mm x 184 mm x 51 mm / 9.6” x 7.2” x 2.0”

Panel Cut-Out (W x H)

220 mm x 160 mm / 8.66” x 6.3”

Maximum Panel Thickness

8 mm / 0.31”

Request a Quote

Product Highlights

Key Features

Specification

DC SUPPLY

CONTINUOUS VOLTAGE RATING8 V to 35 V DC continuous

CRANKING DROPOUTS

Able to survive 0 V for 100 mS, providing supply was at least 10 V before dropout and supply recovers to 5 V. This is achieved without the need for internal batteries. Backlight will not be maintained during cranking.

MAXIMUM OPERATING CURRENT

530 mA at 12 V, 280 mA at 24 V

MAXIMUM STANDBY CURRENT

320 mA at 12 V, 160 mA at 24 V

CHARGE FAIL/EXCITATION RANGE

0 V to 35 V

VOLTAGE MEASUREMENT

NUMBER2

MEASUREMENT INPUTS

3 Phase + Neutral

Generator and Bus

VOLTAGE RANGE

15 V to 415 V Phase to Neutral

25 V to 720 V Phase to Phase

FREQUENCY RANGE

3.5 Hz to 75 Hz

CURRENT TRANSFORMER MEASUREMENT

NUMBER4

MEASUREMENT INPUTS

3 Phase Generator Current with Earth Fault Current

CURRENT RANGE

0 A to 1 A

0 A to 5 A

ANALOGUE INPUTS

NUMBER4

TYPE

Negative Switching Digital Input, Resistive Analogue Input, Current Analogue Inputs or Voltage Analogue Input

DIGITAL INPUTS

NUMBER12

TYPE

Negative Switching Digital Input

EMERGENCY STOP INPUT

NUMBER1

TYPE

Positive Switching Digital Input

MAGNETIC PICK-UP INPUT

VOLTAGE INPUT RANGE0.5 V Peak to 70 V Peak

FREQUENCY INPUT RANGE

1 Hz to 10 kHz

COMMUNICATIONS

USB A

1 Data Storage Port

USB B

1 Programming Port

DSENet®

1 Expansion Port

RS485

2 Fully Isolated RS485 Ports (Second RS485 port available in future update)

RS232

1 Modbus RTU Port

Ethernet

1 10/100 Ethernet Port

CAN

3 Fully Isolated CAN Ports

ECU - Engine ECU/ECm

MSC - MSC Link

CAN - Redundant MSC Link

TEMPERATURE

OPERATING TEMPERATURE

-30 °C to +70 °C / -22 °F to +158 °F

STORAGE TEMPERATURE

-40 °C to +85 °C / -40 °F to +185 °F

DIMENSIONS

OVERALL (W x H x D)

245 mm x 184 mm x 51 mm / 9.6 ” x 7.2 ” x 2.0 ”

PANEL CUT OUT (W x H)

220 mm x 160 mm / 8.66 ” x 6.3 ”

MAXIMUM PANEL THICKNESS

8 mm / 0.31"

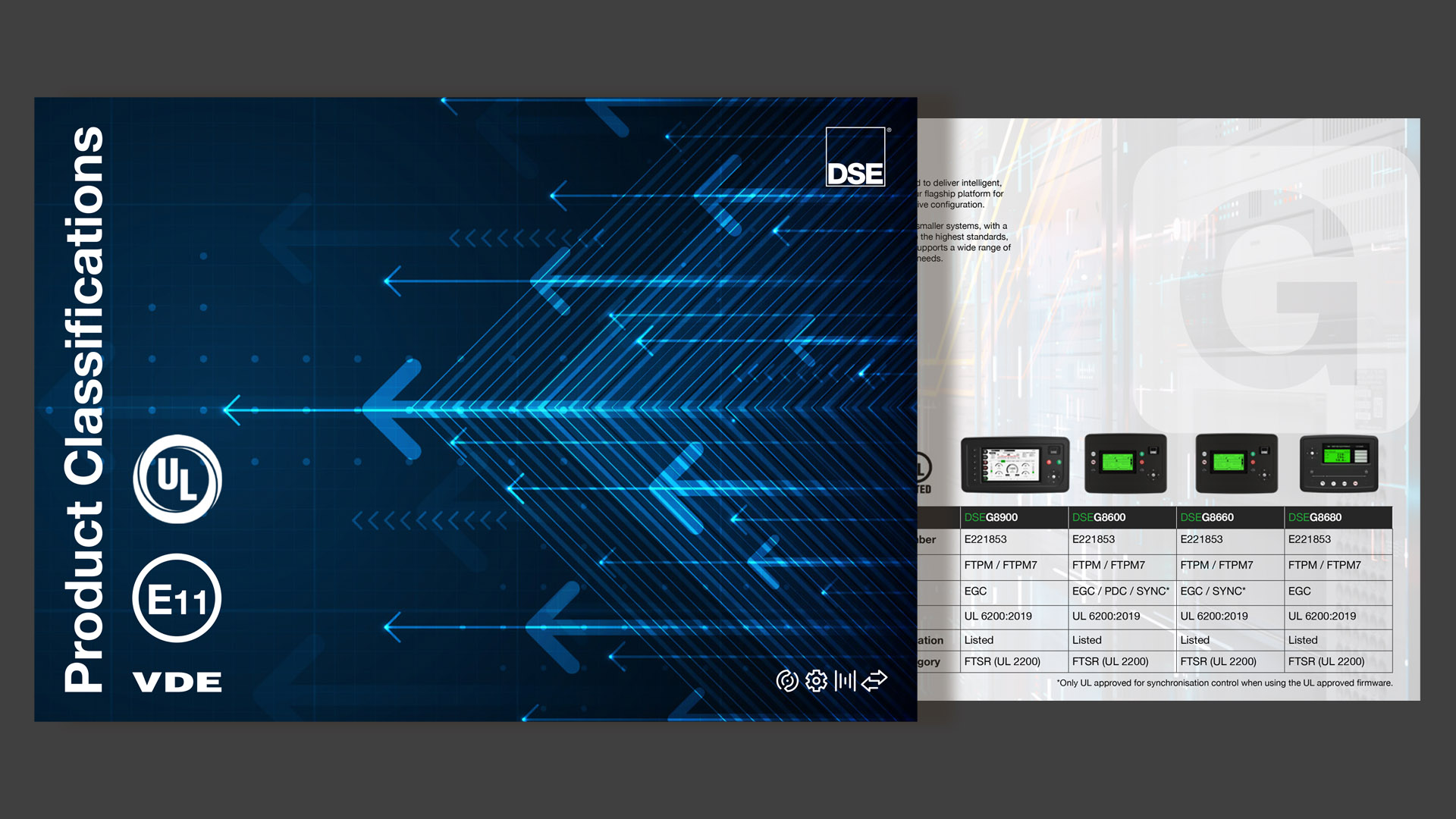

Environmental Testing Standards

ELECTRO-MAGNETIC COMPATIBILITY

ELECTRICAL SAFETY

TEMPERATURE

VIBRATION

HUMIDITY

SHOCK

DEGREES OF PROTECTION PROVIDED BY ENCLOSURES

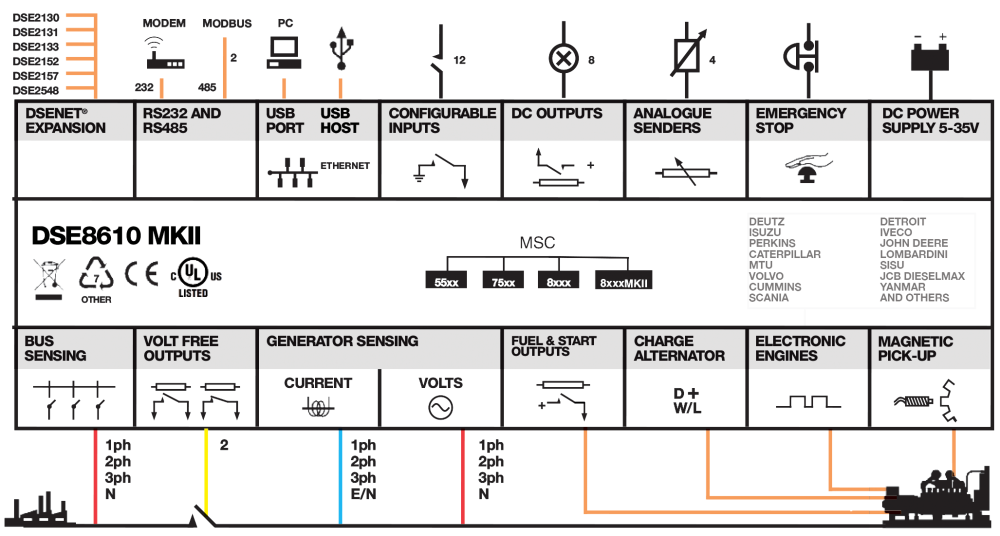

Connection Diagram