Auto Mains (Utility) Failure Control Modules

DSE7420 MKII

Auto Mains (Utility) Failure Control Module

The module is compatible with electronic (CAN) and non-electronic (magnetic pick-up/alternator sensing) engines and offer an extensive number of flexible inputs, outputs and engine protections so the system can be easily adapted to meet the most demanding industry requirements. The comprehensive list of features includes enhanced event and performance monitoring, remote communications & PLC functionality. Dual mutual standby is now available on both the DSE7420 MKII using RS232 or RS485 communications.

250.0 mm x 189.0 mm x 50.5 mm / 9.85 ” x 7.43 ” x 1.99 ”

PANEL CUTOUT SIZE

220.0 mm x 160.0 mm / 8.66 " x 6.30 "

MAXIMUM PANEL THICKNESS

8.0 mm / 0.3 ”

PRODUCT VARIANTS

7420-03

Request a Quote

Product Highlights

Key Features

Specification

DC Supply

CONTINUOUS VOLTAGE RATING8 V to 35 V DC Continuous

CRANKING DROPOUTS

Able to survive 0 V for 100 ms, providing supply was at least 10 V before dropout and supply recovers to 5 V. This is achieved without the need for internal batteries. Backlight will not be maintained during cranking

MAXIMUM OPERATING CURRENT

340 mA at 12 V, 160 mA at 24 V

MAXIMUM STANDBY CURRENT

160 mA at 12 V, 80 mA at 24 V

CHARGE ALTERNATOR EXCITATION / FAIL RANGE

0 V to 35 V

Inputs

ANALOGUE INPUTS

Number: 6

Type: Negative Switching Digital Input (6), Resistive Analogue Input (6), Current Analogue Input (4) and Voltage Analogue Input (4)

DIGITAL INPUTS

Number: 8

Type: Negative Switching Digital Input

EMERGENCY STOP INPUT

Number: 1

Type: Positive Switching Digital Input

MAGNETIC PICK-UP INPUT

Voltage Input Range: 0.5 VPeak to 70 VPeak

Frequency Input Range: 5 Hz to 10 kHz

Outputs

DIGITAL OUTPUTSNumber: 10

Type:

Environmental Testing Standards

ELECTRO-MAGNETIC COMPATIBILITY

BS EN 61000-6-2

EMC Generic Immunity Standard for the Industrial Environment.

BS EN 61000-6-4

EMC Generic Emission Standard for the Industrial Environment.

ELECTRICAL SAFETY

BS EN 60950

Safety of Information Technology Equipment, including Electrical Business Equipment.

TEMPERATURE

BS EN 60068-2-1

Ab/Ae Cold Test -30°C.

BS EN 60068-2-2

Bb/Be Dry Heat +70°C.

VIBRATION

BS EN 60068-2-6

Ten sweeps in each of three major axes.

5 Hz to 8 Hz @ +/-7.5 mm, 8 Hz to 500 Hz @ 2 gn.

HUMIDITY

BS EN 60068-2-30

Db Damp Heat Cyclic 20/55° C @ 95% RH 48 Hours.

BS EN 60068-2-78

Cab Damp Heat Static 40° C @ 93% RH 48 Hours.

SHOCK

BS EN 60068-2-27

Three shocks in each of three major axes 15 gn in 11 ms.

BS EN 60529

IP65 - Front of module when installed into the control panel with the supplied sealing gasket.

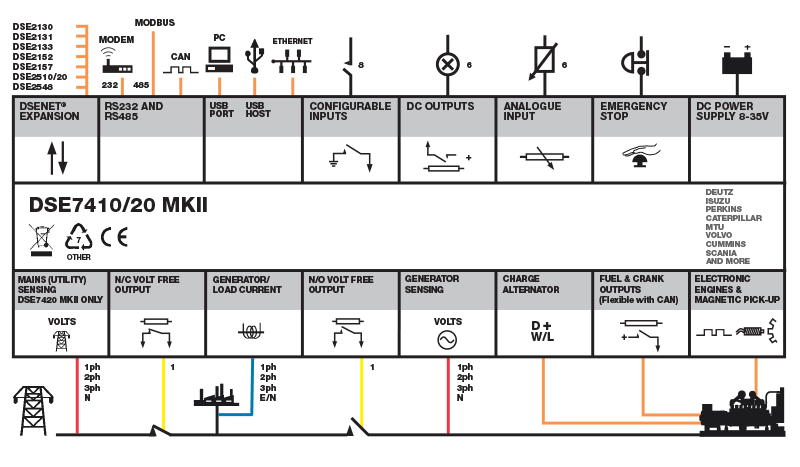

Connection Diagram