Manual & Auto Start Control Modules

DSE4510 MKII

Auto Start Control Module

New Features Added May 2020. Read Product Change Notification Document for details.

140 mm x 113 mm x 43 mm (5.5” x 4.4” x 1.5”)

PANEL CUTOUT SIZE

118 mm x 92 mm (4.6" x 3.6")

MAXIMUM PANEL THICKNESS

8.0 mm (0.3”)

WEIGHT

0.26kg

PRODUCT VARIANTS

4510-05 - 4510 Auto Start Control Module (Ct, Rtc)

This product is now obsolete

and has been replaced with:

DSE4520 MKII –

Auto Mains (Utility) Failure Control Module

Request a Quote

Product Highlights

Key Features

Key Benefits

- Additional Features

- Fuel solenoid pulling circuit

- On-screen line diagram on/off functionality

- Configurable CAN instrumentation (10)

- Water in fuel digital input

- Tank bund alarm digital input

- Generator at rest output

- ECU periodic wake-up for information retrieval

- Back-light power-save mode

- Adjustable delay crank timer

- Pre/post heat functionality

- Overload protection

- Mains/generator A/C system selection

- Output timer for external audible alarm

Specification

DC SUPPLY

CONTINUOUS VOLTAGE RATING

8 V to 35 V Continuous

CRANKING DROPOUTS

Able to survive 0 V for 50 mS, providing supply was at least 10 V before dropout and supply recovers to 5 V. This is achieved without the need for internal batteries. LEDs and backlight will not be maintained during cranking.

MAXIMUM OPERATING CURRENT

85 mA at 12 V, 96 mA at 24 V

MAXIMUM STANDBY CURRENT

51 mA at 12 V, 47 mA at 24 V

MAXIMUM SLEEP CURRENT

35 mA at 12 V, 32 mA at 24 V

MAXIMUM DEEP SLEEP CURRENT

<10 uA at 12 V, <10 uA at 24 V

OUTPUTS

OUTPUT A (FUEL)

10 A short term, 5 A continuous,

at supply voltage

OUTPUT B (START)

10 A short term, 5 A continuous,

at supply voltage

AUXILIARY OUTPUTs C & D

2 A DC at supply voltage

GENERATOR

VOLTAGE RANGE

15 V to 415 V AC (Ph to N)

26 V to 719 V AC (Ph to Ph)

FREQUENCY RANGE

3.5 Hz to 75 Hz

Environmental Testing Standards

ELECTRO-MAGNETIC COMPATIBILITY

BS EN 61000-6-2

EMC Generic Immunity Standard for the Industrial Environment.

BS EN 61000-6-4

EMC Generic Emission Standard for the Industrial Environment.

ELECTRICAL SAFETY

BS EN 60950

Safety of Information Technology Equipment, including Electrical Business Equipment.

TEMPERATURE

BS EN 60068-2-1

Ab/Ae Cold Test -30°C.

BS EN 60068-2-2

Bb/Be Dry Heat +70°C.

VIBRATION

BS EN 60068-2-6

Ten sweeps in each of three major axes.

5 Hz to 8 Hz @ +/-7.5 mm, 8 Hz to 500 Hz @ 2 gn.

HUMIDITY

BS EN 60068-2-30

Db Damp Heat Cyclic 20/55° C @ 95% RH 48 Hours.

BS EN 60068-2-78

Cab Damp Heat Static 40° C @ 93% RH 48 Hours.

SHOCK

BS EN 60068-2-27

Three shocks in each of three major axes 15 gn in 11 ms.

DEGREES OF PROTECTION PROVIDED BY ENCLOSURES

BS EN 60529

IP65 - Front of module when installed into the control panel with the optional sealing gasket.

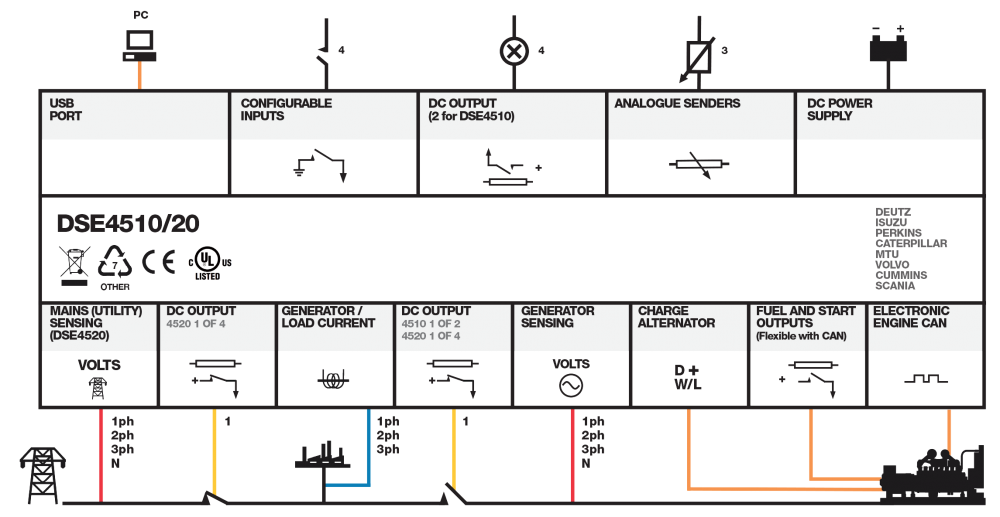

Connection Diagram

Product Variants

4510-35 - RTC/CC