Lighting Tower Control Modules

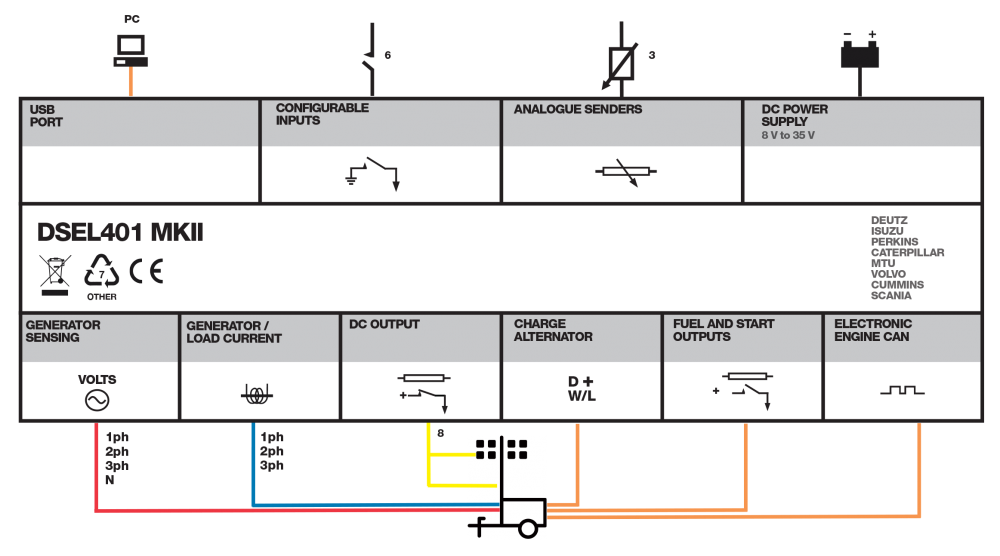

DSEL401 MKII

Intelligent Lighting Tower Control Module

The DSEL401 MKII is an intelligent control module designed specifically for mobile lighting tower applications. The control module provides class leading flexible features that are fully configurable to suit multiple complex lighting sequences.

To view UL Certification click here

140 mm x 113 mm x 43 mm (5.5” x 4.4” x 1.7”)

PANEL CUTOUT SIZE

118 mm x 92 mm (4.6” x 3.6”)

MAXIMUM PANEL THICKNESS

8.0mm (0.3”)

WEIGHT

0.28kg

PRODUCT VARIANTS

L401-01 - L401 MKII Intelligent Lighting Tower Control Module (Rtc)

Request a Quote

Product Highlights

Key Features

Key Benefits

- Additional Features

- Power save mode.

- 3-phase generator sensing.

- Generator/load current monitoring & protection.

- 600 V ph-ph nominal system compatibility.

- Fuel & crank outputs.

- CAN & alternator speed sensing.

- Engine maintenance alarms (3).

- Alternative configuration (1).

Specification

DC SUPPLY

CONTINUOUS VOLTAGE RATING

8 V to 35 V Continuous

CRANKING DROPOUTS

Able to survive 0 V for 50 mS, providing supply was at least 10 V before dropout and supply recovers to 5 V. This is achieved without the need for internal batteries. LEDs and backlight will not be maintained during cranking.

MAXIMUM OPERATING CURRENT

85 mA at 12 V, 96 mA at 24 V

MAXIMUM STANDBY CURRENT

51 mA at 12 V, 47 mA at 24 V

MAXIMUM SLEEP CURRENT

35 mA at 12 V, 32 mA at 24 V

MAXIMUM DEEP SLEEP CURRENT

<10 uA at 12 V, <10 uA at 24 V

OUTPUTS

OUTPUT A (FUEL)10 A short term, 5 A continuous,

at supply voltage

OUTPUT B (START)

10 A short term, 5 A continuous,

at supply voltage

AUXILIARY OUTPUTS C to J

2 A DC at supply voltage

GENERATOR

VOLTAGE RANGE

15 V to 415 V AC (Ph to N)

26 V to 719 V AC (Ph to Ph)

FREQUENCY RANGE

3.5 Hz to 75 Hz

Environmental Testing Standards

ELECTRO-MAGNETIC COMPATIBILITY

BS EN 61000-6-2

EMC Generic Immunity Standard for the Industrial Environment.

BS EN 61000-6-4

EMC Generic Emission Standard for the Industrial Environment.

ELECTRICAL SAFETY

BS EN 60950

Safety of Information Technology Equipment, including Electrical Business Equipment.

TEMPERATURE

BS EN 60068-2-1

Ab/Ae Cold Test -30°C.

BS EN 60068-2-2

Bb/Be Dry Heat +70°C.

VIBRATION

BS EN 60068-2-6

Ten sweeps in each of three major axes.

5 Hz to 8 Hz @ +/-7.5 mm, 8 Hz to 500 Hz @ 2 gn.

HUMIDITY

BS EN 60068-2-30

Db Damp Heat Cyclic 20/55° C @ 95% RH 48 Hours.

BS EN 60068-2-78

Cab Damp Heat Static 40° C @ 93% RH 48 Hours.

SHOCK

BS EN 60068-2-27

Three shocks in each of three major axes 15 gn in 11 ms.

DEGREES OF PROTECTION PROVIDED BY ENCLOSURES

BS EN 60529

IP65 - Front of module when installed into the control panel with the optional sealing gasket.

Connection Diagram

Product Variants

L401-01 - L401 MKII LTC (RTC)