Case studies

View next case study

kDSE86XX Series in Standby Application

Danish paper manufacturer cuts down on costly standstill times with the help of DSE control modules.

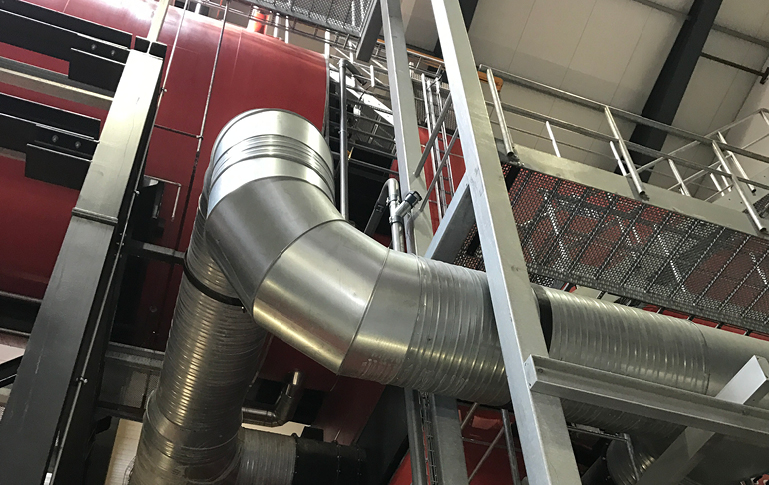

Paper-making processes are complex and largely automated operations with sophisticated equipment working at extremely high speeds. Gas powered furnaces for heating the drying machinery operate at temperatures in excess of 40 degrees C .

Because of the high operating speed and the many sub-processes taking place within the plant, stopping and restarting the paper manufacturing plant is a critical and expensive process. Scheduled and unscheduled standstills must therefore be kept to a minimum to reduce associated high capital costs.

A paper manufacturing plant in Denmark has overcome many standstill problems by operating a stand-by genset system that monitors the incoming mains (utility) supply. In the event of a power failure the genset will automatically start and provide enough power to keep the plant operational. The system operates a no-break automatic return to mains once it returns to within the required parameters, reducing the number of standstills.

The DSE control modules offer highly sophisticated, automatic control & monitoring including a range of built-in features such as sophisticated system reporting & maintenance scheduling which helps align the genset system with the company’s preventative maintenance strategy, further reducing factory standstills.

For further information on the DSE86xx controls please refer to the DSE company website: